| Availability: | |

|---|---|

| Quantity: | |

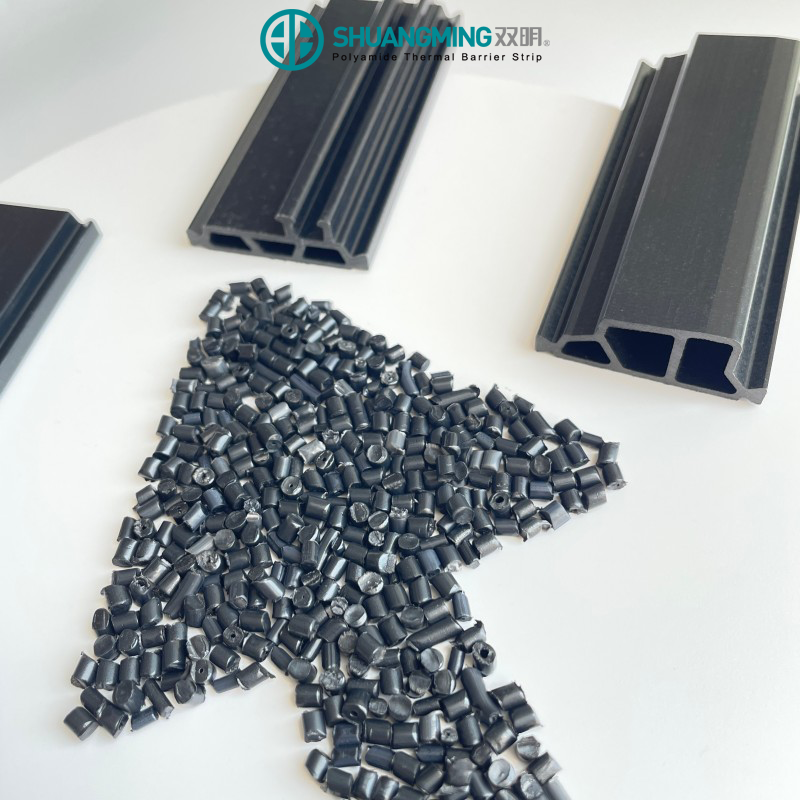

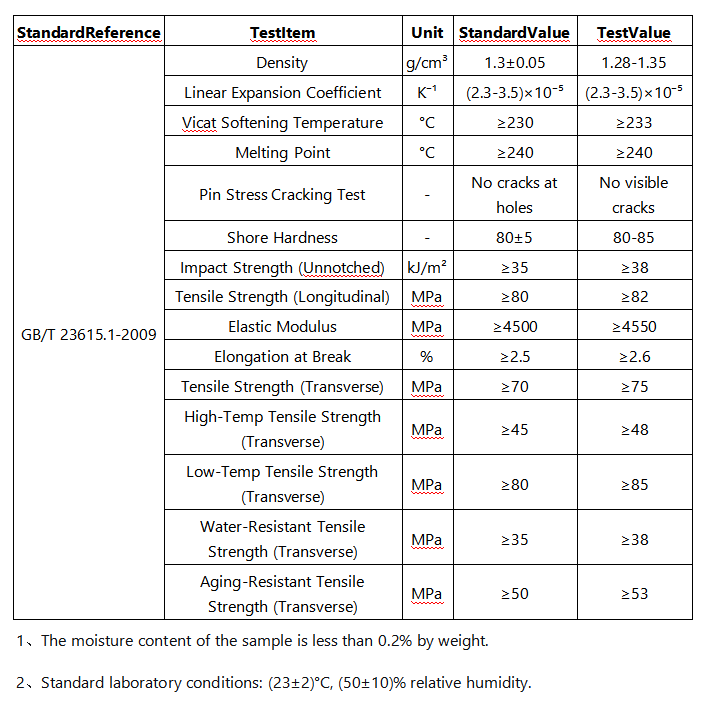

This product utilizes PA66 resin as the matrix material, incorporating glass fibers, high-efficiency flame retardants, and various additives through a twin-screw extrusion process to produce PA66 GF25 granules. The resulting material exhibits excellent mechanical strength, heat resistance, and flame retardancy. The final products manufactured from these granules comply with national standards and are suitable for engineering applications demanding high-performance materials.

Our Polyamide 66 25% glass fiber granules are composed of premium Nylon 66 resin reinforced with 25% glass fiber for superior performance.

Polyamide granular products exhibit high strength and rigidity compared to traditional plastic products.

Products made from Nylon 66 GF25 pellets possess excellent heat resistance, making them suitable for use in various climatic environments.

With strong flame-retardant properties, nylon 66 granule-based products provide thermal insulation and flame resistance in mechanical equipment.

This glass-filled nylon compound delivers exceptional tensile strength and stiffness, making it an ideal metal replacement.

This reinforced polyamide material exhibits strong resistance to oils, fuels, and many chemicals, ensuring longevity.

Q: What is PA66GF25? What are its main components?

A:PA66GF25 is a high-performance engineering plastic granule. It is composed of Polyamide 66 (PA66) resin as the matrix, reinforced with 25% by weight glass fibers (GF). This combination significantly enhances the mechanical strength, rigidity, and heat resistance of the base PA66 resin.

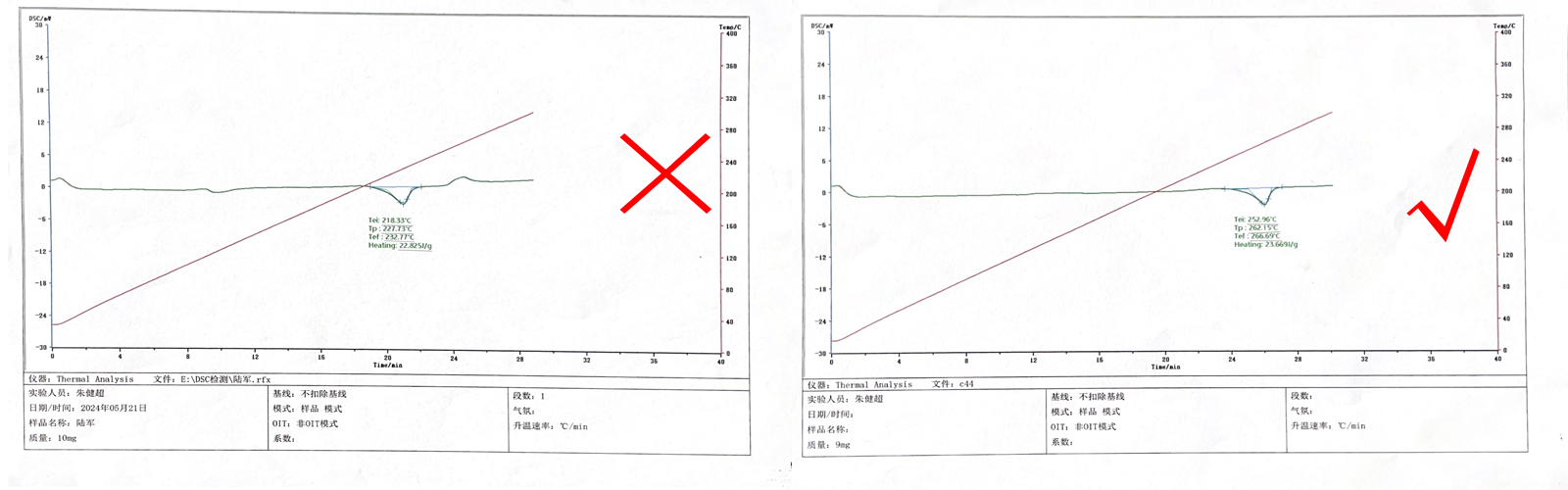

Q: What is the temperature resistance range of PA66 GF25 compound?

A:Its continuous use temperature is typically up to 120-140°C, and it can withstand higher temperatures (e.g., above 180°C) for short periods. The exact value depends on the load and the actual application environment. The Heat Deflection Temperature (HDT at 1.8MPa) is typically above 240°C.

Q: What are the main advantages of PA66GF25 compared to pure PA66?

A: With the addition of 25% glass fibers, PA66GF25 performs exceptionally in the following aspects:

Higher Strength and Rigidity: Tensile strength, flexural strength, and modulus are greatly improved.

Better Heat Resistance: Higher Heat Deflection Temperature (HDT) allows it to maintain shape and performance in more demanding thermal environments.

Lower Creep and Shrinkage: Better dimensional stability results in more precise parts that are less prone to deformation.

Good Wear Resistance: Suitable for components subjected to friction.

content is empty!