| Availability: | |

|---|---|

| Quantity: | |

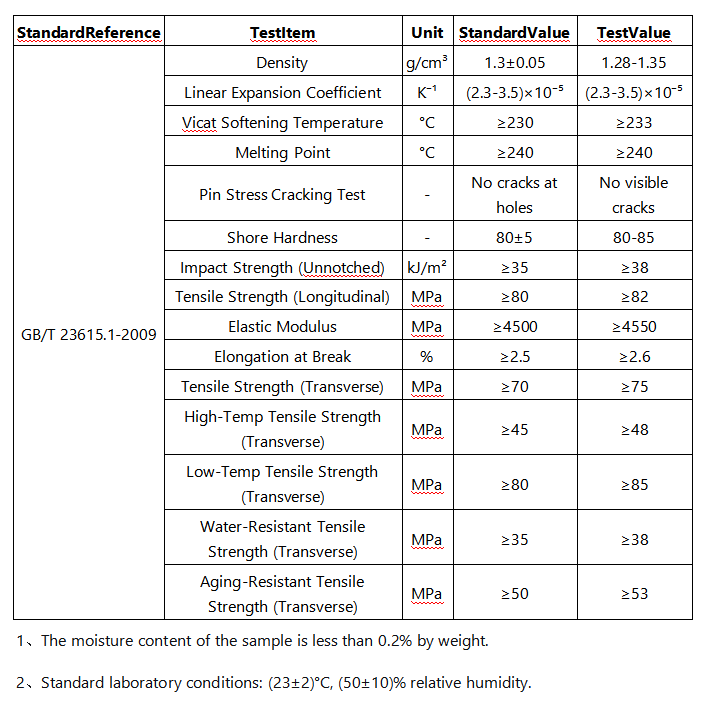

This Polyamide 66 with 25% glass fiber granules is a high-performance engineering plastic specifically modified for enhanced toughness. Building upon the standard glass fiber reinforcement, it is innovatively formulated with special toughening agents. This unique modification allows the material to retain the inherent high rigidity, strength, and heat resistance of the base Nylon 66 resin while dramatically improving its impact resistance and toughness.

Its key features include ultra-high impact toughness, excellent low-temperature performance, and superior resistance to brittle fracture. This ensures that the material maintains exceptional ductility even in frigid or sub-zero environments, preventing catastrophic failure upon sudden impact. Consequently, it is ideally suited for demanding applications where extreme toughness is critical. These include sports equipment subjected to severe impacts, power tool housings that require high safety and durability, and critical automotive anti-collision components, providing a reliable guarantee for product dependability and long service life under challenging conditions.

Our Nylon 66 GF25 pellets widely used in automotive engine compartments for components like fans, gears, and housings due to its heat and chemical resistance.

Nylon itself is hygroscopic, with PA66 having an equilibrium water absorption rate of approximately 2.5%. The addition of reinforcing materials such as glass fibers effectively reduces the impact of water absorption on the dimensional stability of the product, allowing it to maintain more consistent dimensions in varying humidity environments while minimizing shrinkage and deformation. This is particularly important for manufacturing precision structural components.

Glass-filled PA66 25% pellets is a preferred material for electrical connectors, circuit breakers, and switches owing to its insulation and strength.

Our PA66-GF25 engineering plastic ideal for manufacturing durable industrial parts such as bearings, rollers, and machinery housings that require high rigidity.

Q: What are the key parameter recommendations for injection molding PA66GF25?

A: The following are general reference values and should be adjusted for specific molds and machines:

Barrel Temperature: 240°C - 250°C

Injection Speed: Medium to High (Too fast may cause glass fiber orientation, leading to anisotropy)

Back Pressure: Apply moderate back pressure for uniform plastication.

Q: Are there any special requirements for the injection molding machine and mold when processing PA66GF25?

A: Due to the abrasive nature of glass fibers, it is recommended to use:

Wear-Resistant Screw and Barrel:Bimetallic screws/barrels or specially hardened components.

Abrasion-Resistant Mold Steel:Use high-quality, high-hardness mold steel for critical components, with well-designed runners and gates to minimize wear.

Q: How do you ensure the uniform dispersion of glass fibers in the granules?

A: We utilize twin-screw extruders for production. Their high shear force and precise temperature control systems ensure thorough and uniform mixing of the glass fibers with the PA66 resin. We strictly monitor screw configuration, rotation speed, and feeding rates, and regularly conduct microscopic inspection and performance testing to guarantee consistency between batches.

content is empty!