| Availability: | |

|---|---|

| Quantity: | |

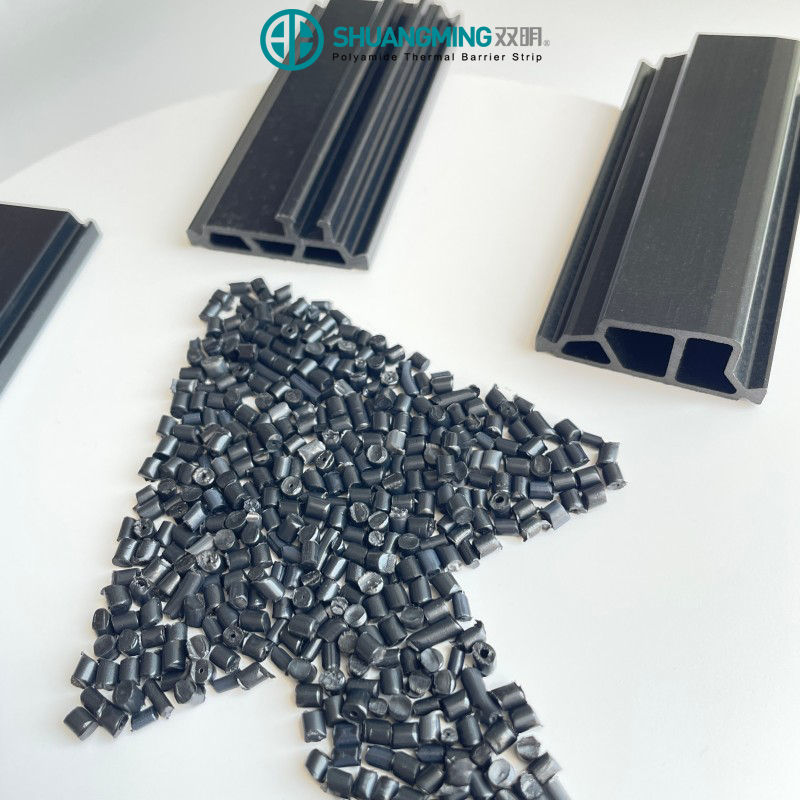

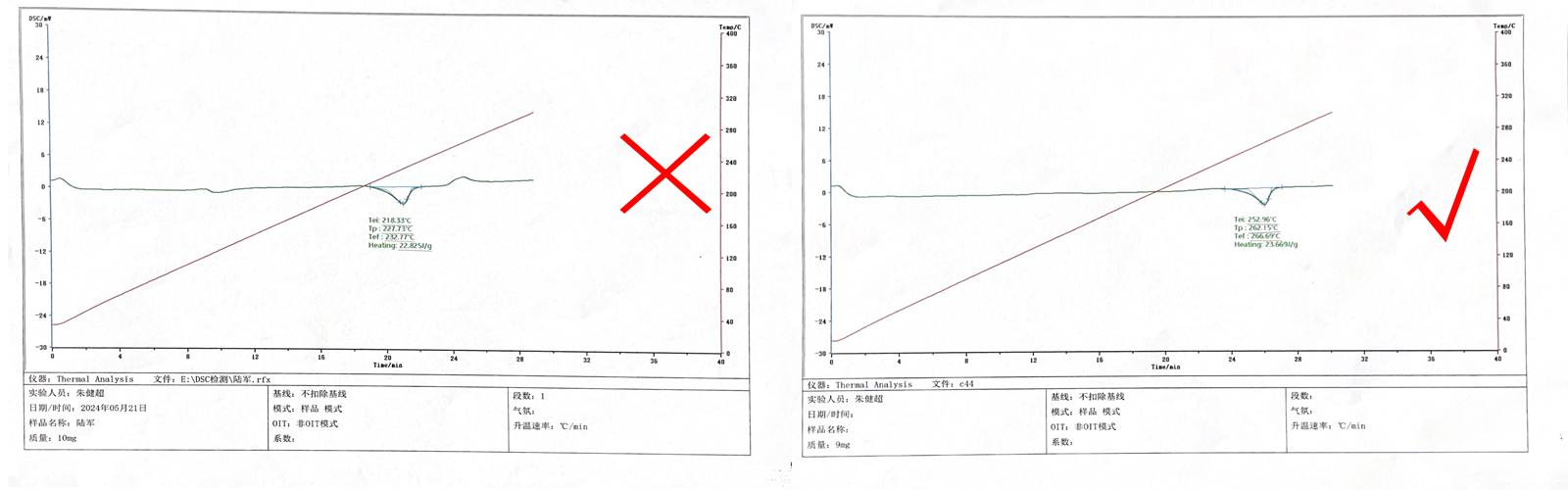

This composite-reinforced PA66 material employs a sophisticated synergistic reinforcement technology, incorporating both glass fibers for core strength and mineral fillers (such as wollastonite) to enhance stiffness and dimensional stability. Within the polymer matrix, these two reinforcement phases perform distinct yet complementary roles: the glass fibers act as the primary load-bearing skeleton, ensuring high strength and impact resistance, while the mineral fillers effectively suppress anisotropic shrinkage during the molding process, thereby significantly reducing component warpage.

Its key features include: very low molding warpage, high dimensional stability, excellent surface flatness, and well-balanced overall performance. This unique combination of properties makes it an ideal choice for manufacturing high-precision, complex-shaped, and large thin-walled structural components, perfectly meeting the modern industrial demands for lightweight design, high strength, and precision molding. Consequently, it is widely used in automotive engine covers, housings for electronic connectors, laptop internal frames, and structural parts in household appliances that require superior shape stability.

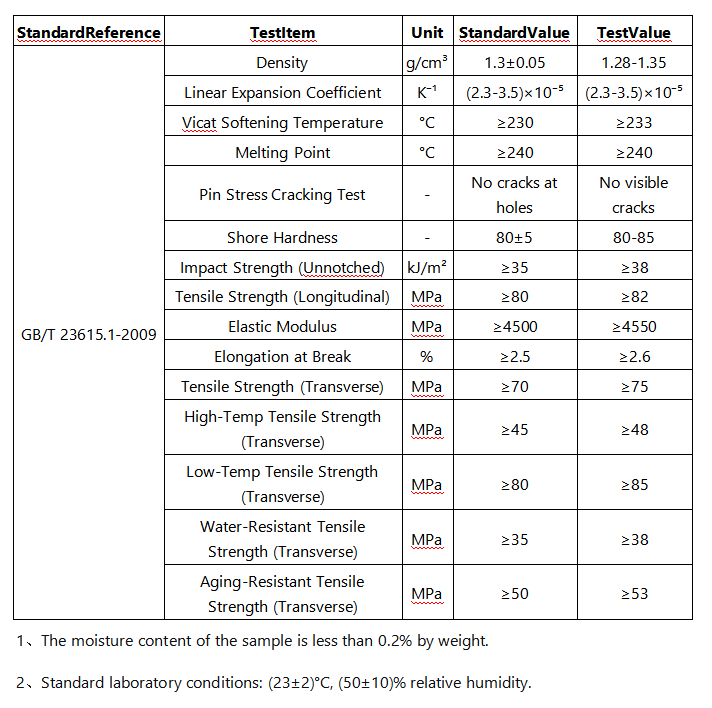

After professional testing, the finished products made of Low-temperature toughened PA66 GF25 have excellent tensile strength (≥85MPa), flexural strength (≥130MPa) and impact strength, which can withstand long-term mechanical stress and are suitable for the production of industrial parts with high structural strength requirements.

Polyamide 66 25% glass fiber granules material offers excellent electrical insulation properties, characterized by high volume resistivity and strong resistance to breakdown voltage, making it an ideal material for manufacturing electrical and electronic components such as connectors, insulating parts, and coil bobbins.

PA66GF25 polyamide particles have excellent high-temperature resistance, with a long-term service temperature of 120-150℃. At the same time, they are resistant to acid, alkali and oil corrosion, and can adapt to complex industrial environments.

Sports-gear PA66 GF25 granules have a stable melt flow index and strong compatibility with mainstream equipment such as injection molding machines and extruders. During processing, problems such as melt fracture and material shortage are not easy to occur, and they can efficiently produce thin-walled parts, precision gears, automotive connectors and other products.

Q: Is this material chemically resistant?

A: PA66GF25 has good resistance to most common chemicals such as oils, greases, hydrocarbons, and certain alcohols. However, it is susceptible to strong acids and oxidizing agents. We recommend testing for specific chemical environments before full-scale use.

Q: What is the moisture absorption of PA66GF25? Does it affect performance?

A: Nylon materials are hygroscopic. Moisture absorption can cause slight dimensional changes (swelling) and temporarily reduce stiffness and strength, while increasing impact toughness. For high-precision parts, it is essential to properly dry the material before processing and account for dimensional changes due to moisture in the design.

Q: In which industries is this material primarily used?

A: It is widely used in automotive parts (e.g., engine covers, fans, connectors), electrical and electronic components (e.g., circuit breakers, sockets, bobbins), industrial equipment (e.g., gears, bearings, guides, tool housings), and sports equipment for structural parts requiring high strength, heat resistance, and wear resistance.

content is empty!