| Availability: | |

|---|---|

| Quantity: | |

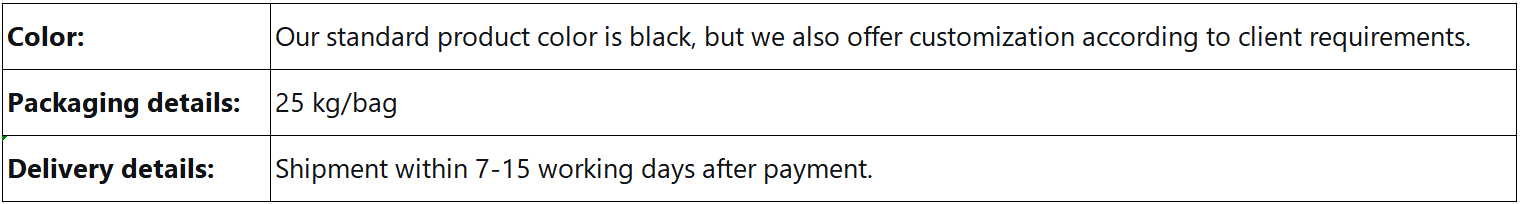

This electroplating-grade PA66 material is specially formulated for optimal compatibility with complex plating processes. Its base resin is engineered to develop an ideal micro-roughened surface during the pre-treatment etching stage, providing a foundational anchor for subsequent activation and electroless plating steps. This ensures exceptional adhesion of the metal coatings (such as copper, nickel, chromium), effectively preventing blistering or peeling.

The plated components successfully merge the lightweight nature and design freedom of plastic with the aesthetic appeal and functional properties of metal. They retain the advantages of being lightweight, easy to mold, and corrosion-resistant, while gaining the high gloss, abrasion resistance, and electromagnetic shielding performance of a metal surface. Key features of this material include: excellent plating adhesion, good melt flow for filling complex molds, and high inherent surface gloss. It is the preferred choice for high-end decorative parts, widely used in automotive grilles, door handles, logo emblems, faucets, and premium cosmetic packaging, meeting integrated demands for aesthetics, lightweighting, and functionality.

In the automotive industry, 3D-printing PA66 GF25 pellets are often used to manufacture engine peripheral components (such as intake pipes, water tank brackets), chassis structural parts and interior skeletons. With their lightweight and high-strength characteristics, they help automobiles reduce energy consumption and improve safety performance.

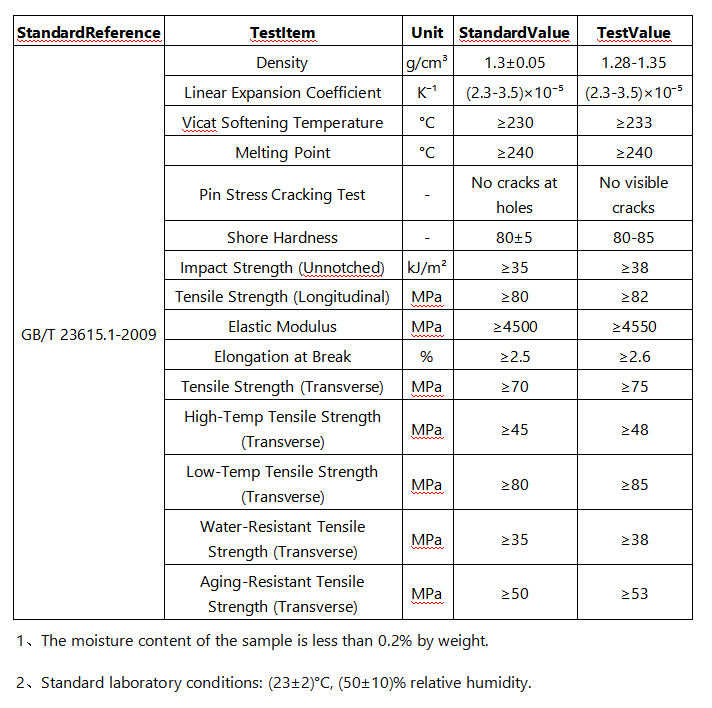

PA66 exhibits certain resistance to acids, alkalis, most inorganic salt solutions, halogenated hydrocarbons, hydrocarbons, esters, ketones, and similar substances. However, it is readily soluble in polar solvents such as phenol and formic acid. This should be noted when selecting materials for specific chemical environments.

In the electronic and electrical field, Food-contact grade PA66 GF25 can be processed into circuit breaker housings, connector pins, motor end covers and other products. Their excellent insulation performance and aging resistance can ensure the long-term stable operation of electronic equipment.

This ROHS compliant PA66 GF25 compound complies with international environmental standards such as RoHS and REACH, does not contain heavy metals and harmful chemicals, and the production process is green and environmentally friendly, which can meet the procurement needs of downstream customers for environmentally friendly raw materials.

Q: Are you the manufacturer? What is your production capacity and quality control?

A: Yes, we are a professional manufacturer with over [e.g., 10 years] of experience. We operate advanced twin-screw extrusion production lines with an annual capacity exceeding [e.g., 10,000] tons. We implement a strict QC system, conducting thorough testing from raw material intake to finished product shipment (e.g., MFI testing, mechanical properties testing) to ensure consistent and reliable performance for every batch.

Q: What customization services do you offer?

A: We offer customization based on client requirements, including: custom colors (using heat-resistant masterbatches), adjusted glass fiber content (e.g., 30%, 35%), addition of other additives (e.g., hydrolysis resistance, toughening, flame retardants), and specific packaging requirements (e.g., 25kg/bag with moisture-proof packaging).

Q: What are the key processing recommendations for PA66GF25?

A: 1. Thorough Drying: Use a dehumidifying dryer at 80-90°C for 4-6 hours to reduce moisture content below 0.1%. 2. Injection Molding Temperature: Barrel temperature is recommended between 270-290°C. 3. Mold Temperature: Recommended at 80-120°C for optimal surface finish and dimensional stability. 4. Screw Design: Use a screw with a non-return valve and wear-resistant coating to minimize shear damage to the glass fibers

content is empty!