| Availability: | |

|---|---|

| Quantity: | |

This self-lubricating grade of PA66-GF25 engineering plastic is formulated with special internal lubricants (such as Molybdenum Disulfide, Silicone, or PTFE) uniformly dispersed within its matrix. This composition significantly enhances the material's tribological properties by facilitating the formation of an effective self-lubricating layer at the friction interface, which dramatically reduces the coefficient of friction and imparts exceptional wear resistance and anti-adhesion characteristics.

Its core advantages include: an extremely low coefficient of friction, outstanding wear resistance, and smooth, low-noise operation. This not only minimizes component wear and energy loss caused by long-term friction but also eliminates the potential contamination and maintenance needs associated with traditional external lubrication. Consequently, it is an ideal choice for manufacturing moving parts that demand high precision, long service life, and quiet operation. It finds widespread application in gears, bearings, sliders, guide rails, and automotive window regulators, significantly improving equipment reliability, efficiency, and operational lifespan.

Enhance the durability and service life of your end-products by utilizing our wear-resistant PA66 GF25 material.

PA66 itself exhibits excellent wear resistance and self-lubricating properties. With the addition of reinforcing fibers, the surface hardness of the material is improved, further significantly enhancing its wear resistance while maintaining a low coefficient of friction. This makes it highly suitable for manufacturing moving parts such as gears, bearings, and sliders that require high wear resistance and low friction.

This product is uniform and rounded UV-stabilized PA66+25%GF pellets, showing a natural milky white color without impurity spots, with good fluidity, which is convenient for accurate feeding in subsequent processing links such as injection molding and extrusion.

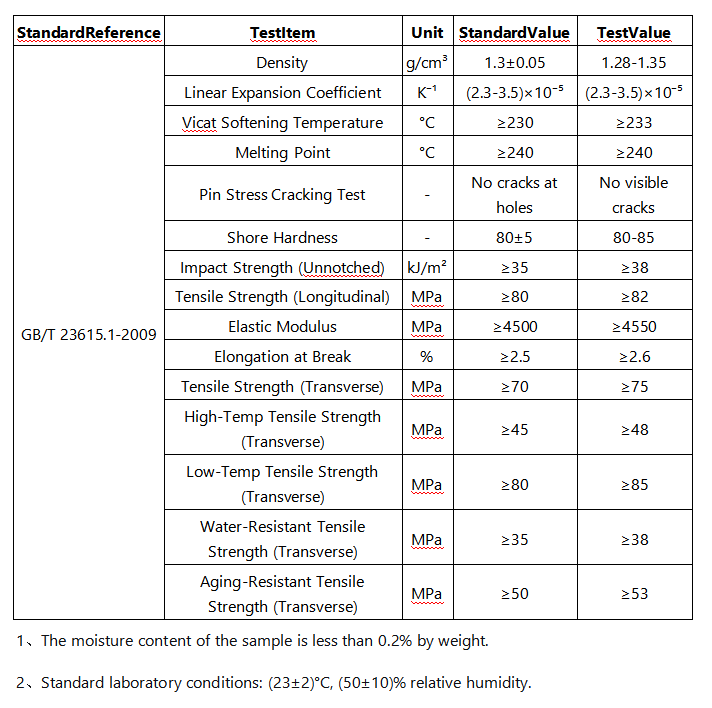

PA66GF25 polyamide particles take high-quality nylon 66 (PA66) as the base material, and are uniformly added with 25% glass fiber (GF) for reinforcement modification. They combine the toughness of the nylon base material and the high strength of glass fiber, and their material stability is far superior to ordinary PA66 particles.

Q: What is PA66GF25? What are its main components?

A: PA66GF25 is a Nylon 66 (Polyamide 66) engineering plastic compound reinforced with 25% Glass Fiber. It combines the excellent mechanical properties of Nylon 66 with the high strength and stiffness provided by glass fiber reinforcement.

Q: What are the main advantages of PA66GF25 compared to pure PA66?

A: Key advantages include: significantly higher tensile and flexural strength; greatly increased heat deflection temperature (HDT); better dimensional stability with lower shrinkage and reduced warpage; improved creep resistance; and better wear resistance.

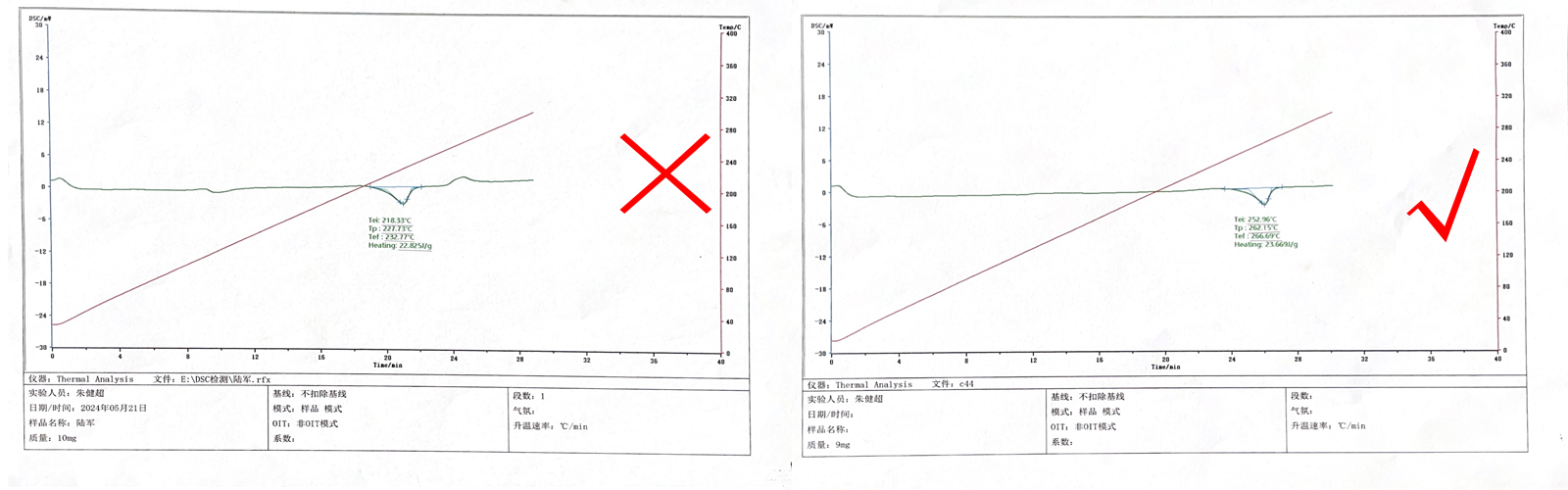

Q: What is the heat resistance temperature of PA66GF25?

A: Its Heat Deflection Temperature (HDT @ 1.82 MPa) typically reaches above 255°C. The continuous service temperature ranges from 80-120°C, with short-term peak temperatures potentially higher depending on the application.

content is empty!