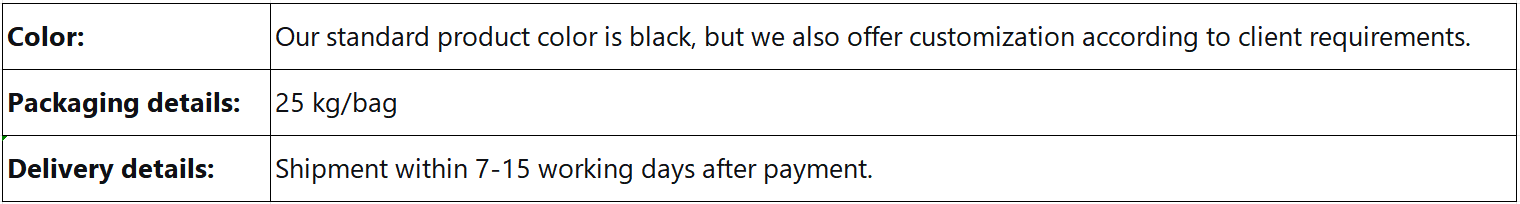

| Availability: | |

|---|---|

| Quantity: | |

This heat-stabilized variant of PA66-GF25 engineering plastic is a specialized solution formulated for demanding, long-term high-temperature applications. By integrating an advanced system of heat stabilizers and antioxidants, the material significantly boosts its resistance to thermal aging when continuously exposed to elevated temperatures. This formulation effectively inhibits molecular chain degradation caused by thermal oxidation, thereby preventing the associated loss of mechanical strength and unwanted discoloration over time.

Its core advantages are: excellent long-term thermal aging stability, remarkable retention of performance at high temperatures, and superior anti-discoloration properties. This ensures that critical mechanical properties, such as strength and rigidity, are maintained at a high level even after prolonged heat exposure, while the visual appearance remains stable. As a result, it is an ideal choice for manufacturing automotive engine peripheral components (e.g., intake manifolds, engine covers), heat-resistant electrical components (like connectors and bobbins), and other electronic parts that must operate reliably in high-temperature environments, guaranteeing exceptional reliability and an extended service life under thermal stress.

These PA66 GF25 pellets are designed for excellent flow characteristics in injection molding, facilitating complex part production.

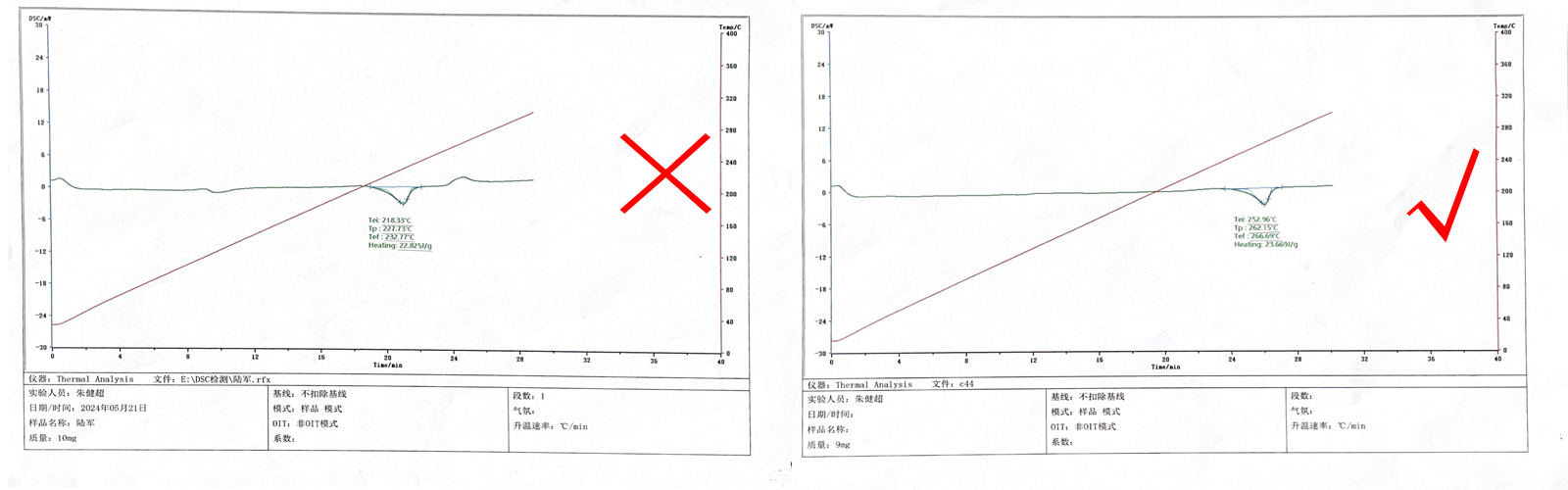

After glass fiber reinforcement, the heat deflection temperature (HDT) of PA66 can be increased to over 250°C, with a continuous service temperature range of approximately 80-120°C and a melting point around 252°C (may vary between 259-267°C depending on testing methods). Its thermal decomposition temperature exceeds 350°C. These properties enable it to adapt to high-temperature working environments such as automotive engine peripherals and electronic-electrical applications.

Reduce cycle times and improve molding efficiency with our consistently 25% fiber glass reinforced PA66.

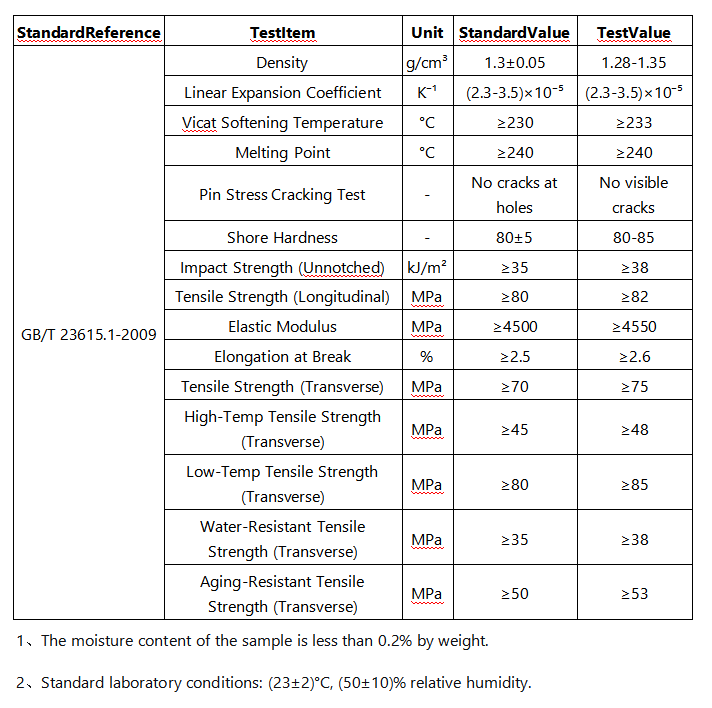

Every batch of our Hot-air dried PA66 GF25 granules undergoes rigorous quality control to ensure it meets precise mechanical and thermal specifications.

Q: What quality certifications and test reports do you provide?

A: Each batch of our products comes with a Certificate of Analysis (COA), including key indicators such as Melt Flow Index (MFI), glass fiber content, tensile strength, impact strength, etc. We can also provide third-party certification reports like SGS and UL Yellow Cards (for flame-retardant grades) upon request. Our manufacturing facility operates under an ISO9001 quality management system.

Q: What is the color and packaging of the product?

A:We supply standard granules in black. Custom colors are available upon request (with a Minimum Order Quantity - MOQ). Standard packaging is 25kg/bag in composite paper-plastic bags with a waterproof inner liner to ensure the product remains dry during transportation and storage. Other packaging options can be arranged per customer requirements.

Q: What is the Minimum Order Quantity (MOQ)?

A:For our standard PA66GF25 product, the MOQ is typically 1 ton. For custom colors or special specifications, the MOQ may be higher. Please consult our sales team for details.

content is empty!