| Availability: | |

|---|---|

| Quantity: | |

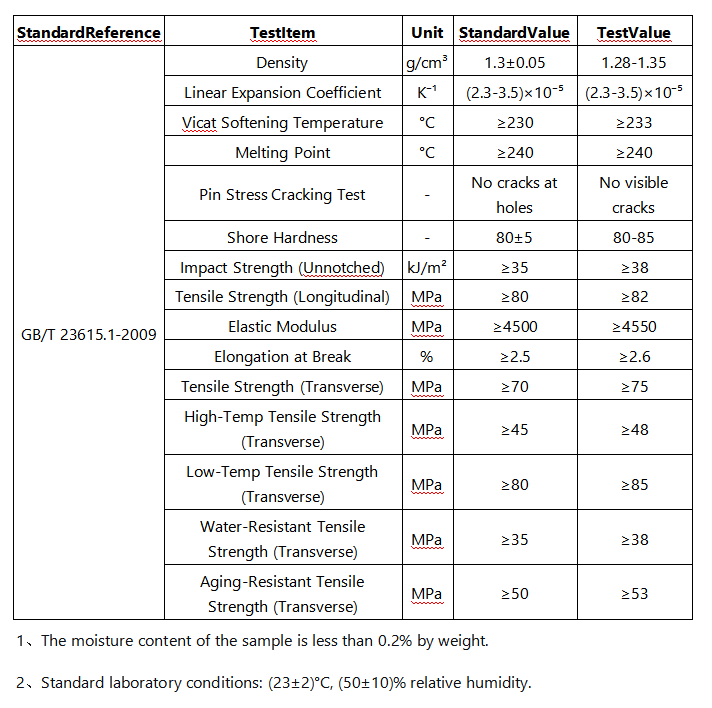

PA66-GF25 engineering plastic is a versatile, high-performance material based on nylon 66 resin reinforced with glass fiber, typically containing 30% glass fiber. It offers outstanding mechanical strength, rigidity, and heat resistance while delivering excellent cost-effectiveness. As an ideal solution for metal replacement and the production of various structural components, it is widely used in automotive, machinery, electronics, electrical appliances, and other industries. This material meets demanding requirements for high strength, lightweight design, and thermal stability, enabling products to achieve an optimal balance of durability, lightweight performance, and economic efficiency.

Key features: High strength, high rigidity, good heat resistance, and high cost-effectiveness.

Engineered for high-temperature environments, 25% fiber glass reinforced PA66 maintains its structural integrity and performance under heat.

PA66 reinforced nylon is modified by adding glass fibers, carbon fibers, or toughening agents. This significantly enhances the material's tensile strength, flexural strength, and rigidity, with fatigue resistance even improving by more than 2.5 times. Products with high glass fiber content generally exhibit superior comprehensive mechanical properties.

Experience excellent dimensional stability with our Halogen-free FR PA66 GF25 pellets, ensuring precise and reliable part manufacturing.

PA66+25%GF plastic raw material offers outstanding creep resistance, which is critical for components under continuous mechanical load.

Q: Is PA66GF25 chemical resistant?

A: PA66GF25 has good resistance to oils and solvents, resisting most common greases, fuels, and weak alkalis. However, it is susceptible to strong acids and oxidizing agents. Compatibility testing is recommended for use in specific chemical environments.

Q: Does this material require drying before processing?

A: Yes, it is mandatory. PA66 resin is hygroscopic. If the moisture content is too high, hydrolysis will occur at high temperatures during injection molding, leading to molecular chain degradation. This causes bubbles, silver streaks, surface defects, and a severe reduction in mechanical properties. Recommended drying conditions: 4-6 hours at 80-90°C to achieve a moisture content below 0.15%.

Q: What are the typical applications and products for PA66GF25?

A: Its high strength, rigidity, and heat resistance make it widely used in:

Automotive Industry: Engine covers, radiator end tanks, fan blades, door handles, various gears and bearings.

Electronics & Electrical: Circuit breaker housings, connectors, bobbins, sockets.

Industrial Machinery: Gears, cams, bearing cages, pump housings, tool handles.

Consumer Goods: Power tool housings, sports equipment, furniture components.

content is empty!