| Availability: | |

|---|---|

| Quantity: | |

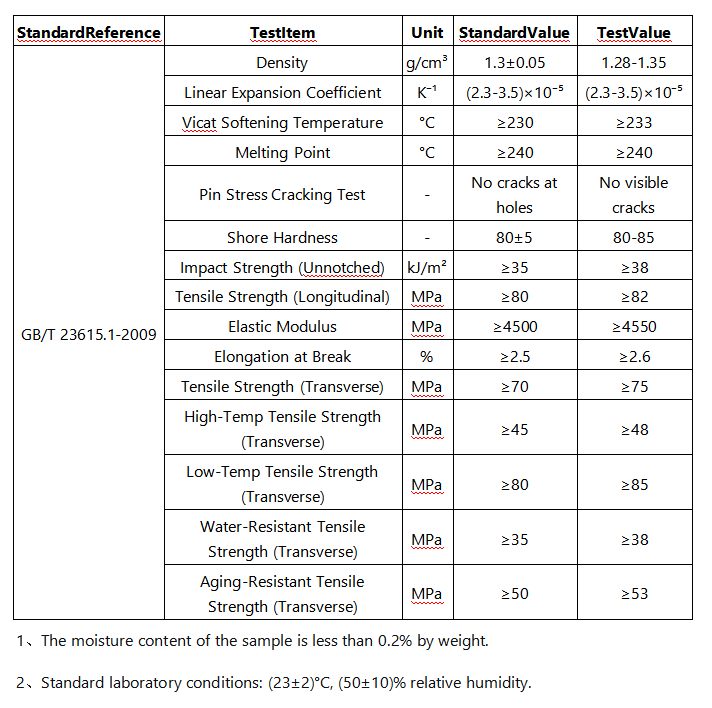

This weather-resistant PA66 engineering plastic is specifically formulated to withstand harsh outdoor conditions. It incorporates a composite protective system of high-efficiency UV absorbers and stabilizers, which work by absorbing and dissipating the damaging energy of ultraviolet radiation, thereby significantly delaying the photo-oxidative degradation process caused by prolonged exposure to sunlight, rain, and wind.

Its core advantages are excellent UV resistance and robust overall weatherability. Even after extended outdoor service, the material maintains remarkable retention of mechanical properties (such as impact and tensile strength) and color stability, effectively preventing common issues like embrittlement, chalking, cracking, or fading. This makes it ideally suited for manufacturing high-durability outdoor products, including electrical enclosures, gardening equipment, outdoor lighting components, sports gear, and automotive exterior trims, ensuring consistent appearance and reliable performance throughout the product's entire lifespan.

The particle size of Halogen-free FR PA66 GF25 pellets is controlled at 2-4mm, and the particle uniformity is over 98%. It is packaged in moisture-proof kraft paper bags (25kg/bag) or ton bags, which is convenient for storage and transportation, and effectively prevents the particles from absorbing moisture and deteriorating.

Reinforced Lubricated PA66 GF25 granules typically exhibit good melt flow properties, facilitating ease of injection molding and making them suitable for producing complex and thin-walled parts. During processing, note the following: the material may require drying to prevent moisture-induced degradation; the melt temperature generally ranges between 260-290°C, with glass-filled grades recommended at 275-280°C, avoiding temperatures exceeding 300°C; mold temperature influences crystallinity and is typically advised to be maintained between 60-100°C.

Compared with ordinary Electrically neutral PA66 GF25 compound, PA66GF25 particles have a flexural strength increase of about 60% and a heat distortion temperature increase of 30-50℃ due to the addition of 25% glass fiber, which can meet high-strength and high-temperature application scenarios that ordinary Hydrolysis-resistant PA66+GF25 pellets cannot adapt to.

Our Radiator-end-tank PA66+GF25 pellets is a polyamide 66 engineering plastic granule reinforced with 25% glass fiber. It significantly enhances the mechanical strength, rigidity, and heat deflection temperature (HDT) of the base resin while maintaining excellent dimensional stability. This material is a cost-effective solution for high-strength, heat-resistant components, widely used in automotive engine compartments, electrical connectors, power tool housings, and more.

Q: Does processing cause significant mold and machine wear?

A: Yes, the 25% glass fiber content increases abrasiveness compared to unfilled resins. We recommend using wear-resistant steel (e.g., STAVAX) for critical mold components (e.g., gates, runners) and employing surface-hardened screws and barrels to extend equipment life.

Q: What is the Minimum Order Quantity (MOQ)?

A: Our standard MOQ is one pallet (approx. 500-600 kg). For trial orders from new clients, we can offer more flexible options. Please contact our sales team for details.

Q: What is the typical lead time?

A: For standard grades and colors, the lead time is typically 10-15 working days after receiving the deposit. Lead times for customized products (e.g., new colors, special formulations) will be longer and confirmed case by case.

content is empty!

content is empty!